Backcountry Equipment

The goal is to make lighter, more durable gear either from scratch or improving existing tools.

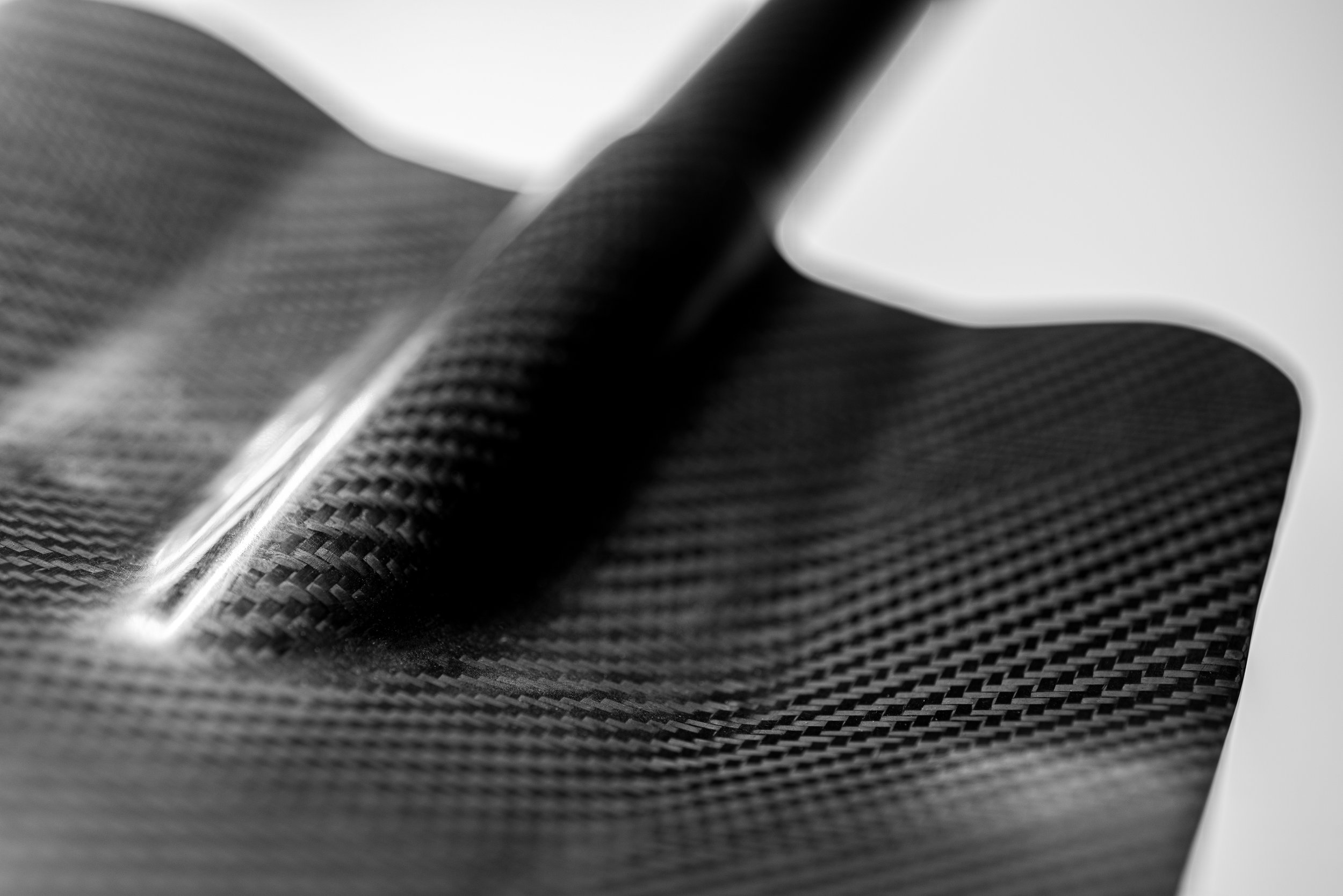

We are presently working on a sub one pound avalanche rescue shovel made from composites and 3D printed parts from Tempus here in Trail BC. The blade was made at Selkirk College in Trail in a collaboration with students in the DFAB program (https://selkirk.ca/programs/arts/digital-fabrication-and-design-diploma) and made at the STAC facility. We have 2 prototypes we have been testing and will continue to test this season. Our plan is to have these used by ski guides, forecasters, recreational users and ski patrollers to find any potential weaknesses. Our goal is to ultimately make an indestructible, lightweight tool that will last a lifetime. We are confident that we can design and build every piece of this in Trail hopefully inspiring further collaboration with DFAB students and local industry.

The goal was to make the lightest, best cutting snow saw. We buy Silky replacement Zubat 330mm blades. Why? They are the best. Then we laser etch 1 and 2 mm crystal grids and 5cm graduations up to 30mm for quick reference if you’re doing an ECT test. We have made custom 3D printed light weight handles and sheaths, again using Tempus 3D made right here in Trail BC. The saw minus sheath weighs 180g and with about 325g. We are already working on an even lighter version of the sheath that in no way sacrifices the durability. The proximity to our manufacturing and design facility (a 8 km bike ride!) allows us to almost instantly refine our products.

This is another project that was a collaboration with the DFAB program and STAC (shout out to Owen for his fantastic design work on both the saw project and shovel)